Intelligent boiler condition monitoring

We successfully applied a total of twenty (20) EUvis insitu systems at boilers with operating temperatures up to 1,250 °C to monitor and analyze sooting and slagging. By means of state-of-the-art image processing technology the thickness of deposits are continuously determined with high accuracy.

The condition of the boiler tubes has a significant influence on boiler operation and efficiency. Slagging and fouling reduce the heat exchanger efficiency, disturb the local heat balance and require expensive on-load cleaning. Worse, slagging and fouling may prove irreversible if corrective action is not initiated in a timely manner. Excessive cleaning, however, leads to tube ruptures – the root cause of many forced outages.

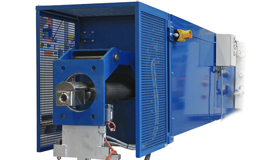

EUvis insitu is a one-of-a-kind fully insertable camera system. It traverses the boiler under full load operation to constantly monitor the condition of the boiler tubes.

Call us or send us

an email!