Improve your power plant efficiency!

- Correct and reliable measurement of air-fuel-ratio, coal mass flow, coal fineness, coal velocity, particle size distribution, flame temperature

- Continuous boiler monitoring

- Identification of slagging and fouling

- Fuel savings through intelligent control strategies

- Performance improvement through combustion process optimization

Stay competitive and reduce CO2 emissions!

- Modular and easily adaptable solutions

- Quick project implementation

- Retrofitting strategies

- Full utilization of data potentials

- Innovative methods using model-based design

- 3 step approach: Measurement – Control – Optimization

Find the solution for your specific needs

EUcoalsizer™ measures the particle size distribution and the coal and air flow inside a measurement volume that is placed at the tip of an insertable lance. The results are available in real-time and open up possibilities for optimization.

EUcoalflow™ is an online system for dynamic coal flow monitoring and balancing. It is based on non-intrusive micro-wave sensors which continuously measure the mass flow and coal velocity inside coal pipes and quantify the imbalance of coal flow from pipe to pipe.

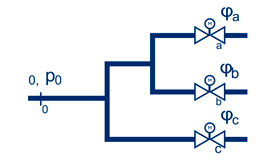

EUsoft air™ is a next generation virtual sensor. Essentially, it is a clever piece of software that continuously determines the complete air flows from readily available DCS data.

EUflame™ is an optical sensor based system specially designed for the application in fossil-fired steam generators to measure the furnace exit gas temperature (FEGT).

EUvis™ is a specially designed monitoring system for online analysis of combustion processes inside furnaces. It helps to keep close track of the process and operating conditions, and identifies problem areas early in advance. The powerful software tool helps to automatically analyze and evaluate process information - such as flame position and deposit thickness - using edge detection algorithms.

EUvis insitu™ is a one-of-a-kind fully insertable camera system. It traverses the boiler under full load operation to constantly monitor the condition of the boiler tubes.

Total AFR™ Management is a real-time air-fuel control system that considers relevant parameters to exploit the full potential of power plants. It enables the direct adjustment of the air-fuel-ratio, which is the key-driver of combustion.

EUcontrol™ extracts available system information and uses it for intelligent control and optimization objectives: Increasing combustion efficiency, lowering emissions and reducing slagging/fouling tendencies in fossil-fired steam generators.