Dynamic effects of a varying mill classifier speed

For the first time the effect of a varying centrifugal classifier speed on coal particle size distribution and coal flow distribution between burners was monitored online in a large scale utility boiler. For this purpose Laborelec, a technical competence centre in electrical power and energy technology, relied on the EUcoalsizer and EUcoalflow systems. “Applied Thermal Engineering” recently published a research paper with the results.

Highlights

• The effect of a coal mill classifier speed was measured online in a 660MWe plant.

• The coal particle fineness and the coal flow distribution were monitored.

• The amount of particles <75 μm varied between 66 and 74%.

• The maximum coal flow deviation was reduced from 14% to 9%.

Abstract

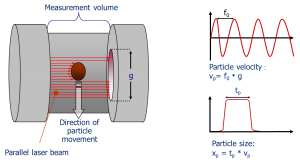

The fineness of the coal powder and the uniformity of the coal flow sent to the burners are crucial parameters to achieve an effective combustion in coal-fired power plants. This study presents a methodology for the online monitoring of the (i) coal particle size distribution and (ii) coal flow distribution between burners at the outlet of a roller mill installed in 660 MWe coal-fired power plant. The effect of a varying centrifugal classifier speed on these two properties was investigated. To the best knowledge of the authors, it is the first time that such an effect is monitored online in a large scale utility boiler. For a classifier speed between 73 and 99 rpm, the mass fraction of particles smaller than 75 µm varied between 66 and 74%. The coal flow distribution between burners was strongly improved when the particle size was the smallest: the maximum deviation from the average flow rate was reduced from 14% at 73 rpm to 9% at 99 rpm.

Receive access to the complete article: “Online monitoring of coal particle size and flow distribution in coal-fired power plants: Dynamic effects of a varying mill classifier speed”